SPB Taper Lock Pulleys Used with B or SPB / XPB Section Belts

SPB Pulleys are used with B or SPB / XPB Section Belts. This section has a single groove to ten groove taper lock pulley. The pulleys are mounted to the shafts using the Taper bushes. The Taper bush does not only secure the pulley on the shaft with a keyway but also fixes it against axial displacement. The SPB V-belt pulleys for Taper bush meet the highest requirements of modern drive technology and are used in all areas of mechanical engineering, from fine mechanics to heavy engineering. They are typically used in compressors, blowers, machine tools, paper and chemical industries, and many other machines.

As one of the taper lock pulley manufacturers, suppliers, and exporters of mechanical products, We offer taper lock pulley and many other products. Please get in touch with us for details.

Mail:[email protected]

SPB Pulleys are used with B or SPB / XPB Section Belts. This section has a single groove to ten groove taper lock pulley. The pulleys are mounted to the shafts using the Taper bushes. The Taper bush does not only secure the pulley on the shaft with a keyway but also fixes it against axial displacement. The SPB V-belt pulleys for Taper bush meet the highest requirements of modern drive technology and are used in all areas of mechanical engineering, from fine mechanics to heavy engineering. They are typically used in compressors, blowers, machine tools, paper and chemical industries, and many other machines.

(1) SPB 01/02

| SPB 01 | SPB 02 |

|

|

|

|

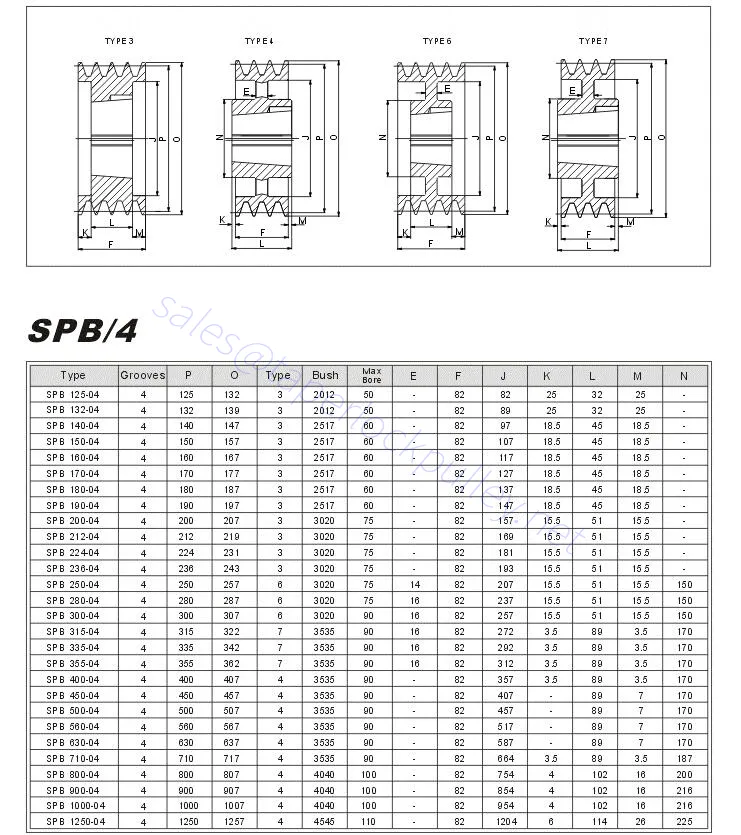

(2) SPB 03/04

| SPB 03 | SPB 04 |

|

|

|

|

(3) SPB 05/06

| SPB 05 | SPB 06 |

|

|

|

|

(4) SPB 08/10

| SPB 08 | SPB 10 |

|

|

|

|

SPB taper lock pulleys belong to the hub type parts, generally relatively large in size, and the manufacturing process is generally based on casting and forging. Generally, the larger size is designed by the casting method, and the material is generally cast iron (good casting performance), and cast steel is rarely used (the casting performance of steel is not good). Generally, the smaller size can be designed for forging.

The Advantages of SPB Taper Lock Pulley Drive:

The pulley drive can ease the load impact;

The pulley drive runs smoothly, with low noise and vibration;

The structure of the pulley drive is simple and the adjustment is convenient;

The pulley drive is not as strict as the mesh drive for the manufacturing and installation accuracy of the pulley;

The pulley drive has the function of overload protection;

The center distance of the two axles driven by the pulley has a large adjustment range.

The disadvantages of belt drive are:

The pulley transmission has elastic sliding and slipping, the transmission efficiency is low and the accurate transmission ratio cannot be maintained;

When the pulley transmission transmits the same large circumferential force, the contour size and the pressure on the shaft are larger than the meshing transmission;

Pulley drive belts have a shorter lifespan.

Applications of Taper Lock Pulleys :

- Taper lock pulleys are used in a variety of industrial applications, including machine tools, textile machines, and conveyor belts.

- Taper lock pulleys are used to transmit power from a motor to a load.

- Taper lock pulleys can be used in both single and multiple pulley systems.

- Taper lock pulleys are available in a variety of sizes and shapes to meet the needs of different applications.

XinLan – The Best Taper Lock Pulley Supplier

XinLan offers a wide range of v belt pulleys, timing pulleys, and taper lock pulleys for a variety of industrial and commercial applications. As a leading taper lock pulley supplier, we provide the highest quality pulleys that are designed to withstand the most demanding environments.

Our taper lock pulleys are made from the highest quality materials and are precision-crafted to ensure accurate fit and precise operation. We offer a variety of pulley sizes and styles to meet your specific needs.

The standard size range includes SPA Pulley, SPB Pulley, and SPC Pulley and are equivalent to HZPT Pulley in Quality. You can buy standard Taper lock Pulleys or send us the design and drawing for Custom Variable

Material available for Taperlock Pulleys.

- Cast Iron Taper Bush in Locking Pulley

- Steel Taper lock Bush Pulley.

- Stainless Steel Taper Pulley

- Aluminum

If you need a taper lock pulley, contact us today to learn more about our products and services.

Pulley Production Process

A V-pulley manufacturing process includes the following steps:

Forming a pulley: integrally forming a cylindrical pulley blank;

machining V-belt grooves: cutting the external surface of the pulley blank to form a plurality of V-belt grooves matching a V belt;

Fine machining: cutting the external surface of the pulley blank and the side surfaces of the belt grooves, and cutting off a machining allowance;

Shot blasting: Place the pulley in a shot blasting machine to form a rough shot blasting layer on the side surfaces of the V-belt grooves. The pulley manufactured through the above process has a high friction coefficient of the side surfaces of the belt grooves and therefore has the advantage of preventing slippage and having high transmission efficiency.